Calibration

Only the regular calibration of test equipment ensures a permanently test reliability!

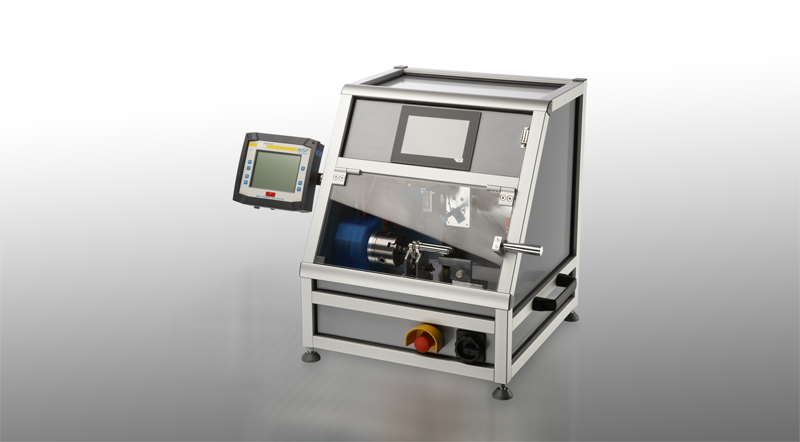

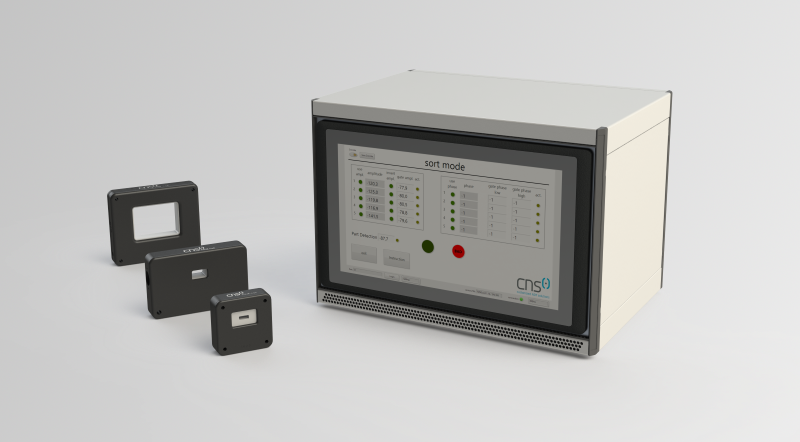

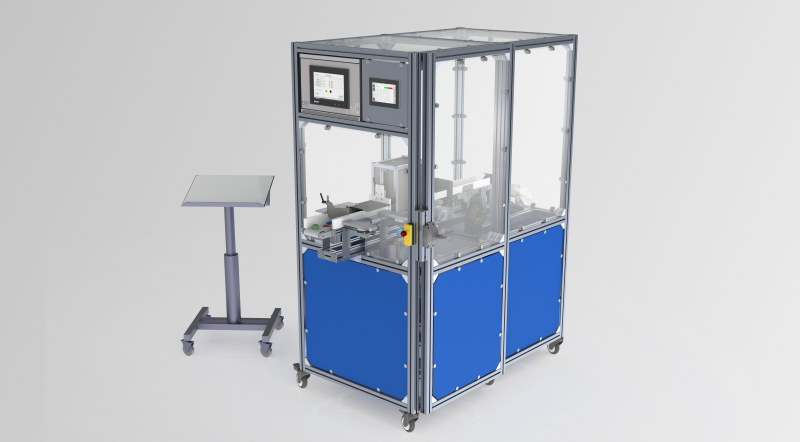

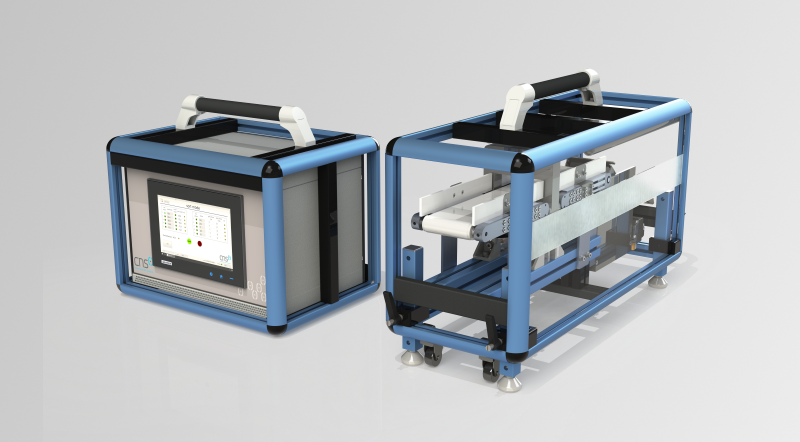

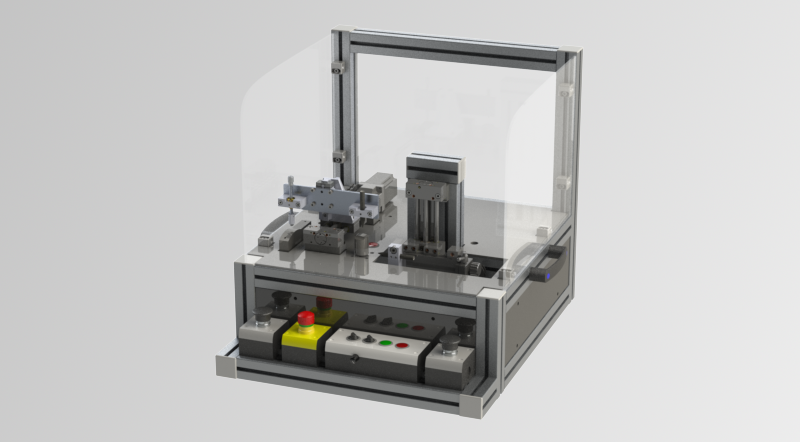

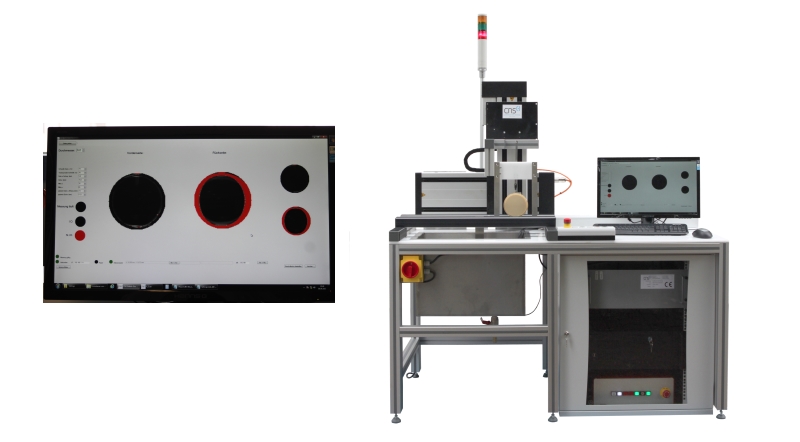

As partner of the company Rohmann we take care of calibration of your eddy current devices.

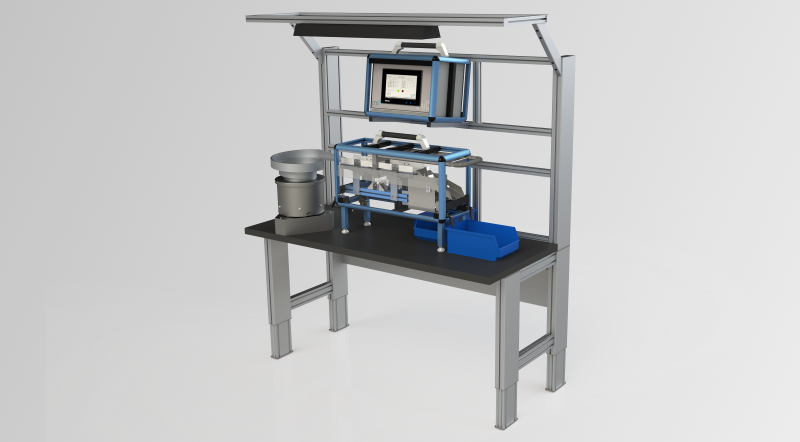

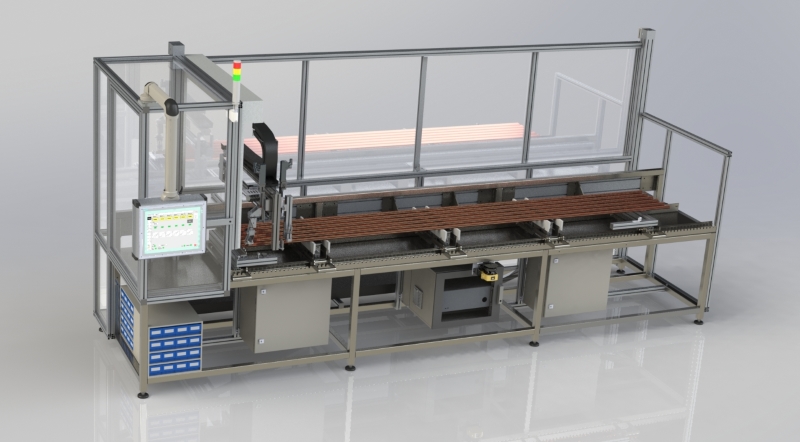

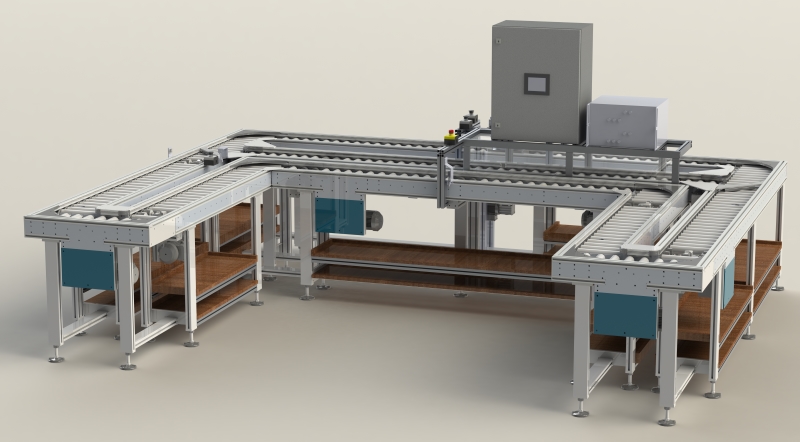

Calibration is carried out either by the manufacturer in Frankenthal or directly at your place in the production line. To avoid production failures you may borrow a rental device at us.