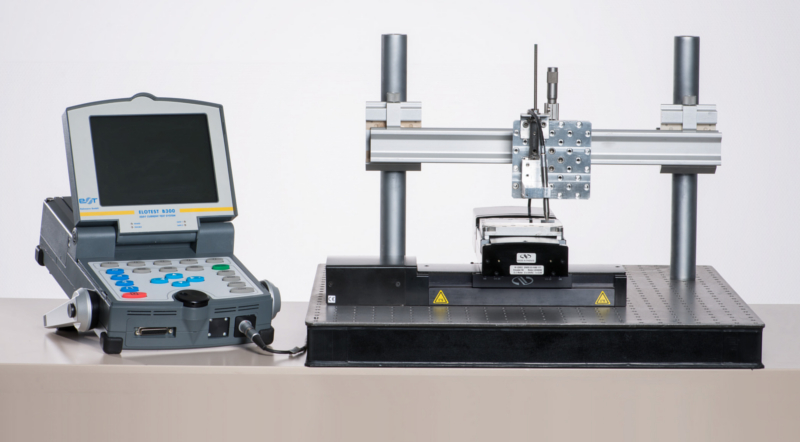

Eddy Current Testing (ET)

Eddy current testing is suitable for fast and efficient testing of all electrically conductive materials.

The testing is contactless and can be automated to a high degree. In addition to “classic” crack testing, this technology is also used for microstructure monitoring.

Inspection tasks:

• Crack testing (open and hidden cracks)

• Contamination of materials (foreign inclusions)

• Determination of conductivity and coating thickness

• Hardness determination (hardness increase, hardening depth)

• heat treatment monitoring

• grinding burn test

• corrosion test

• Determination of residual wall thickness